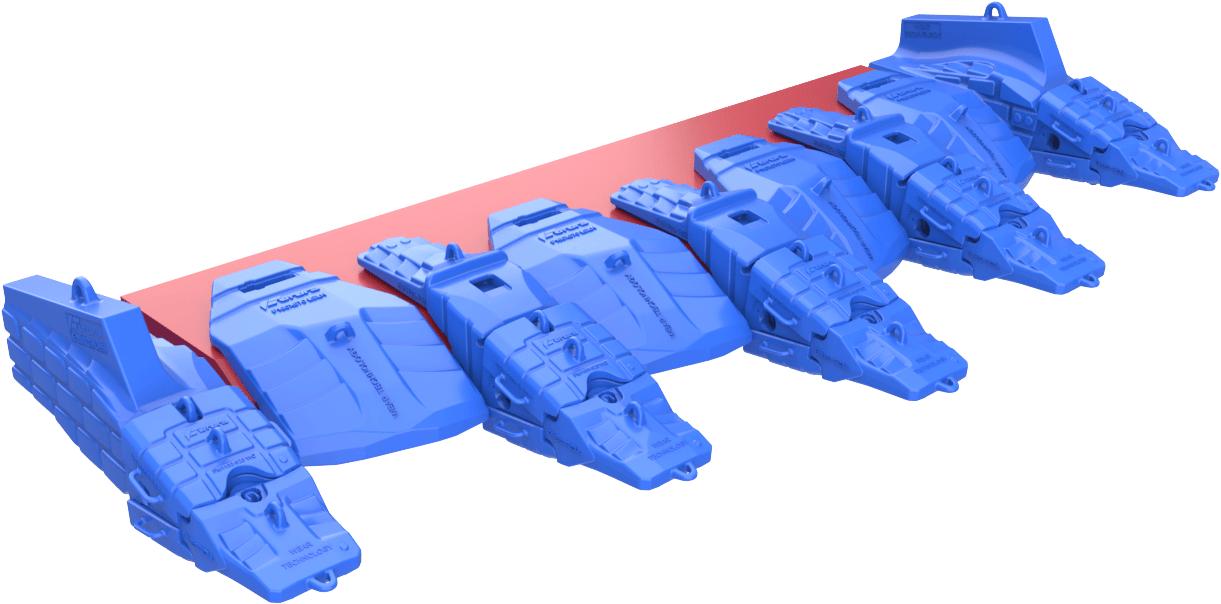

Futura Excavator Bucket Lip Assemblies are a weld-in machined cutting edge pre-installed with Futura adapters, teeth, and lip shrouds. Cut the old lip out and replace it with a new Futura lip assembly, ready to work.

We design and fabricate Futura Excavator Bucket Lip Assemblies for 54-136 tonne class excavators. They are compatible with Cat 352, 374, 395, 6015; Komatsu PC490, PC650, PC900, PC1250; Hitachi ZX490, ZX530, ZX690, ZX890, EX1200; Volvo EC480, EC500, EC530, EC550, EC750, EC950; Develon DX490, DX530, DX800, DX1000; Sany SY500, SY550, SY650, SY750, SY870, SY980, SY1250; Hyundai HX480, HX520, HX800, HX1000; Liebherr R956, R960, R972, R978, R992, R998; and other similar models. For larger excavators, see our Mining Excavator Bucket Lips. For smaller excavators, see our Construction Excavator Bucket Lips.

We offer either a straight or spade (delta) cutting edge up to 160mm / 6.3” thick, and a combination of Futura quarry GET solutions designed to improve bucket lip performance and simplify maintenance.

Yes. We fabricate OEM replacement excavator bucket lip profiles or custom designs to match your bucket width, wear requirements, and operating conditions.

We provide a selection of abrasion-resistant steel brands for excavator cutting edges, including Hardox, JFE, and Bisalloy, matched to your specific application and preferences.