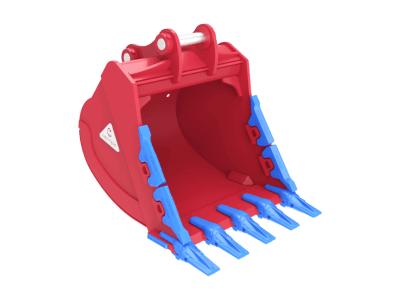

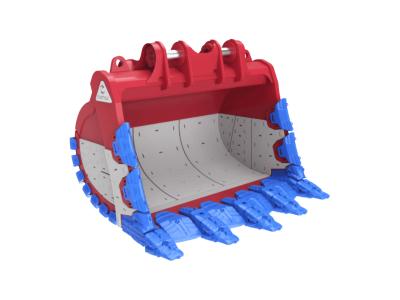

Enstruc Wear Solutions designs and manufactures buckets and attachments, ground engaging tools, and wear parts that deliver strength, reliability, and long service life for construction, quarrying, and mining operations worldwide.

From mining buckets and GET systems to long reach booms, rippers, and undercarriage components, Enstruc heavy equipment attachments and wear parts are engineered for consistent performance, precise fitment, and easy maintenance across all site conditions.

Delivering to over 40 countries from 6 locations, Enstruc knows what it takes to efficiently transport heavy equipment attachments and wear parts around the world.

Whether it’s containers of bucket teeth and undercarriage parts, or huge mining buckets and long reach excavator arms, we ensure your assets are delivered safely and efficiently to any location.

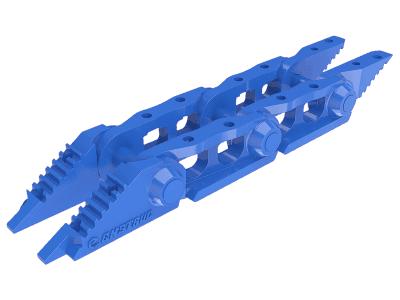

Task: After years of using multiple brands of load haul dump (LHD) ground engaging tools (GET) and wear parts on their fleet of mining LHD buckets, Enstruc was tasked with developing better wear material and lowering manufacturing costs to produce a more productive and cost efficient underground LHD GET system.

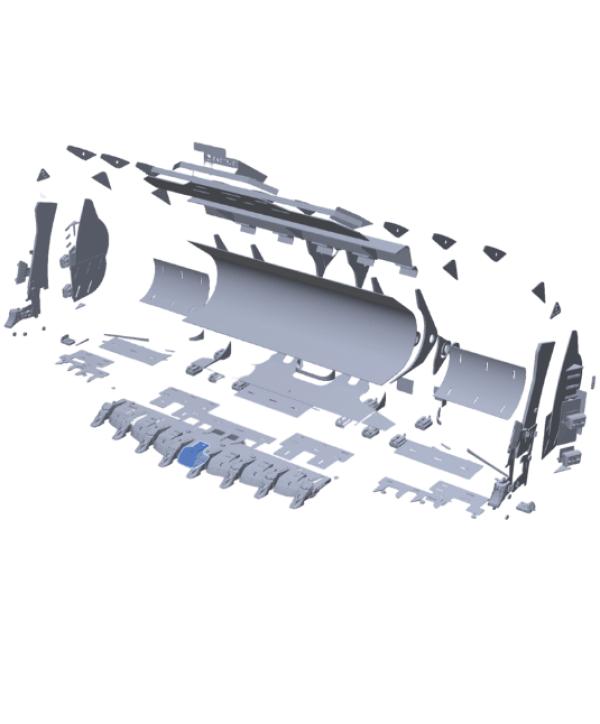

Action: Working closely with our teams, Enstruc engineered a recipe of high performance steel alloys and expedited the efficient production of moulds, prototypes, and bulk cast parts with robust product testing, inspection and delivery according to customer requirements.

Outcome: The Enstruc LHD GET wear material outperformed the previous LHD bucket lip system in terms of wear life and cost per hour, delivering an annual GET savings of over $47,000 for a single underground mining loader.

Enstruc custom-engineers buckets and attachments, ground engaging tools (GET), specialised wear parts, and undercarriage components. Whether you have a design ready for production or need full engineering and global manufacturing support, we deliver high-performance solutions built for productivity. From concept to completion, we help you get exactly what you need, on-time and on-budget.